ʻO nā koi hoʻolālā o kahi mea kanu hana alkyl glycoside e pili ana i ka synthesis Fisher e hilinaʻi nui ʻia i ke ʻano o ka carbohydrate i hoʻohana ʻia a me ka lōʻihi o ke kaulahao o ka waiʻona i hoʻohana ʻia. Alkyl polyglycosides no ka DP i hāʻawi ʻia, ʻaʻole hiki ke hoʻoheheʻe ʻia i loko o ka wai ma muli o ka waiʻona i hoʻohana ʻia (ka helu o nā ʻātoma C i ka alkyl chian≥16) e hoʻokaʻawale ʻia.

Ma lalo o ke kūlana o ka alkyl polyglucoside synthesis catalyzed e ka waikawa, hana ʻia nā huahana lua e like me ka polyglucose ether a me nā haumia kala. ʻO ka hana ʻana o polyglycosides i nā makahiki i hala iho nei e hōʻemi i ka hoʻokumu ʻana o nā huahana lua e pili ana i ka synthesis.

Ma keʻano laulā, loaʻa nā pilikia hana liʻiliʻi loa nā alkyl glycosides i hoʻokumu ʻia i ka waiʻona pōkole (C8/10-OH) a me ka DP haʻahaʻa. I ka hopena hopena, me ka piʻi ʻana o ka waiʻona nui, e emi ana ka hana o nā huahana lua. Hoʻemi ia i ke kaumaha wela a hoʻoneʻe i ka waiʻona nui i ka wā o ka hoʻokumu ʻana o nā huahana pyrolysis.

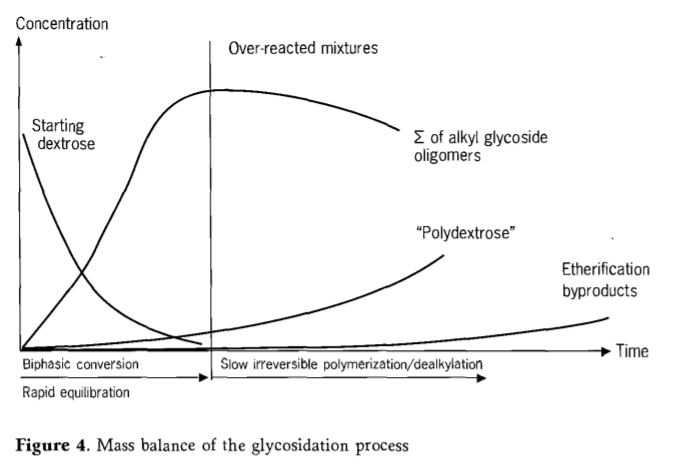

Hiki ke wehewehe ʻia ʻo Fisher glycosidation ma ke ʻano he kaʻina hana e hoʻokō wikiwiki ai ka glucose i ka pae mua a loaʻa ka oligomer equilibrium. Ua ukali ʻia kēia ʻanuʻu e ka hoʻohaʻahaʻa lohi o ka alkyl glycosides. ʻO ke kaʻina degradation e pili ana i nā pae e like me dealkylation a me ka polymerization, i ka hoʻonui ʻia ʻana, hiki ʻole ke hoʻokumu i kahi thermodynamically ʻoi aku ka paʻa o ka hopena i kapa ʻia ka polyglucose. Hoʻopau mua ʻia, aia ka nui o ke koena glucose i ka hui ʻana o ka hopena.

ʻO ka nalowale o nā mea ikaika o ka alkyl glucoside i ka hui ʻana he pilina maikaʻi me ka hoʻokumu ʻana o polyglucose. I ka nui o ka hopena, e lilo ana ka huila hopena i polyphase ma muli o ka ua o ka polyglucose. No laila, e hoʻopilikia nui ʻia ka maikaʻi o ka huahana a me ka hua o ka huahana i ka manawa o ka hoʻopau ʻana. pane aku.

Ma ke kaʻina hana i hoʻopaʻa ʻia, ʻoi aku ka haʻahaʻa o ka huahana etherification (e pili ana i ka mahana o ka hopena, ka manawa, ke ʻano o ka catalyst a me ka ʻike, etc.).

Hōʻike ka Figure 4 i ke ʻano maʻamau o ka hopena pololei o ka dextrose a me ka momona momona (C12/14-OH).

ʻO ka mahana a me ke kaomi o nā mea hoʻohālikelike e pili pono ana kekahi i kekahi i ka hopena fischer glycation.

Alkyl polyglycosides haʻahaʻa i nā huahana lua ma muli o nā wela haʻahaʻa haʻahaʻa (<100 ℃) i ka acetalization. Eia nō naʻe, ʻo ka haʻahaʻa haʻahaʻa ka hopena i nā manawa hoʻonā lōʻihi (ma muli o ke kaulahao o ka waiʻona) a me nā haʻahaʻa haʻahaʻa haʻahaʻa. Hiki ke hoʻololi i ka waihoʻoluʻu o nā haʻahaʻa haʻahaʻa i nā wela wela (> 100 ℃, maʻamau 110-120 ℃). Ma ka wehe ʻana i nā huahana hoʻoheheʻe haʻahaʻa haʻahaʻa (ka wai i ka synthesis pololei, nā ʻawaʻawa kaulahao pōkole i ke kaʻina transacetalization) mai ka hui ʻana, ua hoʻololi ʻia ka equilibrium acetalization i ka ʻaoʻao huahana. Inā hoʻopuka ʻia ka nui o ka wai i kēlā me kēia ʻāpana o ka manawa, no ka laʻana e nā wela hoʻololi kiʻekiʻe, pono e hoʻolako ʻia no ka wehe pono ʻana i kēia wai mai ka hui ʻana. Hoʻemi kēia i nā hopena lua (ʻoi aku ka hoʻokumu ʻana o polydextrose) i hana ʻia i mua o ka wai. ʻAʻole hilinaʻi wale ka evaporation evaporation o kahi pae pane wale nō ma ke kaomi, akā pū kekahi wahi evaporation, etc. ʻO ke kaomi ʻana maʻamau i ka transacetalization a me nā ʻano like ʻole synthesis ma waena o 20 a me 100mbar.

ʻO kekahi mea nui optimization kumu ka hoʻomohala ʻana o nā catalysts koho i ke kaʻina glycosidation, no laila ke kāohi nei, no ka laʻana, ka hoʻokumu ʻana o ka polyglucose a me ka etherification. E like me ka mea i haʻi mua ʻia, acetal a i ʻole reverse acetal i Fischer synthesis e catalyzed e nā waikawa. ʻO ka hopena o ka hopena e pili ana i ka ʻakika a me ka neʻe ʻana o ka ʻakika i loko o ka waiʻona. ʻO nā hopena lua i hiki ke hoʻopaʻa ʻia e nā waikawa (e laʻa, polyglucose hoʻokumu ʻia) e hana nui ʻia i loko o ka māhele polar (trace water) o ka hui ʻana, a me nā kaulahao alkyl i hiki ke hoʻemi ʻia e ka hoʻohana ʻana i nā waikawa hydrophobic (e laʻa, alkyl poʻoʻona poʻomanaʻo liʻiliʻi i loko o ka hopena o ka ʻakika alkyl prilyesulf) huikau.

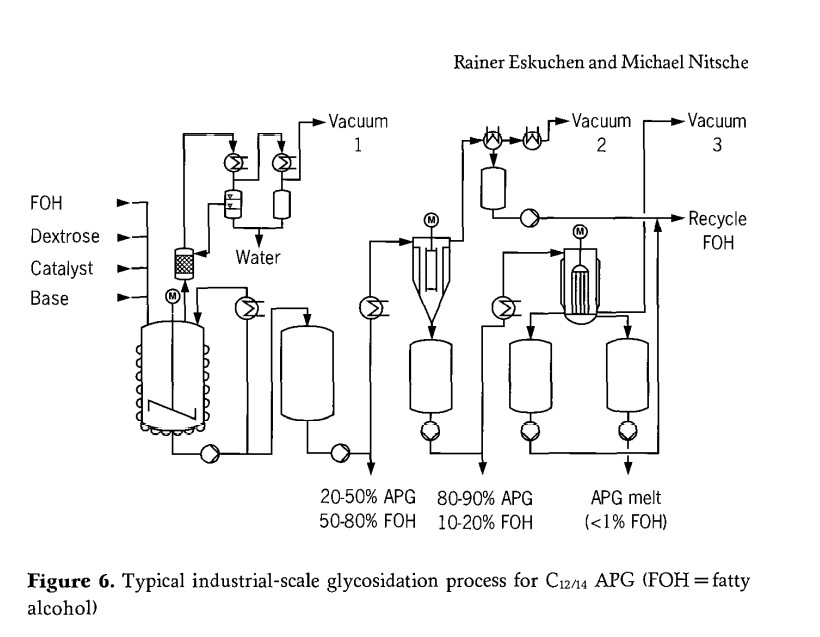

Ma hope o ka pane ʻana, hoʻokaʻawale ʻia ka mea hoʻoheheʻe waika me kahi kumu kūpono, e like me ka sodium hydroxide a me ka magnesium oxide. ʻO ka hui ʻana i hoʻohālikelike ʻia he hopena melemele ʻeleʻele i loaʻa ka 50 a 80 pakeneka mau momona momona. ʻO ke kiʻekiʻe o ka waiʻona momona ma muli o ka ratio molar o nā carbohydrates i nā momona momona. Hoʻoponopono ʻia kēia ratio no ka loaʻa ʻana o kahi DP kikoʻī no nā polyglycosides alkyl ʻoihana, a ma waena o 1:2 a me 1:6.

Hoʻopau ʻia ka waiʻona momona nui ma o ka distillation vacuum. ʻO nā kūlana palena koʻikoʻi he:

- Pono ke koena o ka waiʻona momona i loko o ka huahana<1% no ka mea ʻē aʻe

hoʻopilikia maikaʻi ʻia ka solubility a me ka ʻala.

- No ka hoʻohaʻahaʻa ʻana i ka hana ʻana o nā huahana pyrolysis makemake ʻole a i ʻole nā mea wehe ʻole, pono e mālama ʻia ke koʻikoʻi wela a me ka manawa noho o ka huahana i hoʻopaʻa ʻia i ka haʻahaʻa me ka hilinaʻi i ka lōʻihi o ke kaulahao.

- ʻAʻole pono e komo ka monoglycoside i loko o ka distillate no ka mea ua hoʻihoʻi hou ʻia ka distillate i ka hopena e like me ka waiʻona momona maʻemaʻe.

Ma ka hihia o dodecanol/tetradecanol, ua hoʻohana ʻia kēia mau koi no ka wehe ʻana i nā ʻawaʻawa momona momona, i ʻoluʻolu loa ma o ka multistage ditillation. He mea nui e hoʻomaopopo i ka emi ʻana o ka ʻona o ka momona momona, piʻi nui ka viscosity. Hoʻopilikia kēia i ka wela a me ka hoʻoili nui ʻana i ka māhele distillation hope.

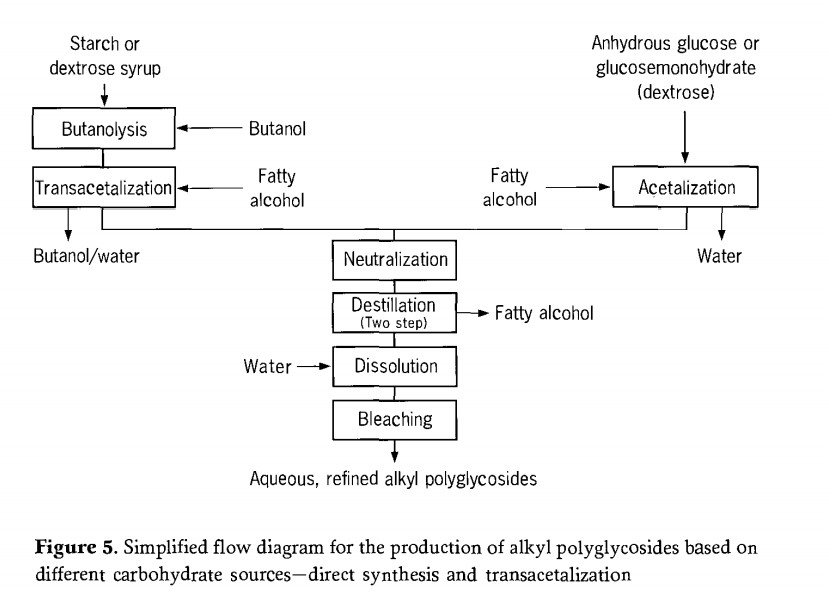

No laila, makemake ʻia nā evaporators lahilahi a pōkole paha. I loko o kēia mau evaporators, hāʻawi ka kiʻiʻoniʻoni mechanically neʻe ʻoi aku ka kiʻekiʻe ma mua o ka maikaʻi o ka evaporation a me ka manawa o ka noho ʻana o ka huahana pōkole, a me ka vacuum maikaʻi. ʻO ka huahana hope loa ma hope o ka distillation he alkyl polyglycoside kokoke i maʻemaʻe, e hōʻiliʻili ʻia me kahi paʻa me kahi helu heheʻe o 70 ℃ a 150 ℃. Ua hōʻuluʻulu ʻia nā ʻanuʻu hana nui o ka synthesis alkyl e like me ke Kiʻi 5.

Ma muli o ke kaʻina hana i hoʻohana ʻia, hoʻokahi a ʻelua mau kahe waiʻona e hōʻiliʻili i ka hana ʻana o ka polyglycoside alkyl; nā waiʻona momona momona, akā hiki ke hoʻihoʻi hou ʻia nā ʻawaʻawa kaulahao pōkole. Hiki ke hoʻohana hou ʻia kēia mau ʻona i nā hopena hope. ʻO ka pono no ka hoʻomaʻemaʻe ʻana a i ʻole ke alapine o ka hoʻomaʻemaʻe ʻana i nā hana hoʻomaʻemaʻe e pili ana i nā haumia i hōʻiliʻili ʻia i loko o ka waiʻona. Aia kēia ma muli o ka maikaʻi o nā kaʻina hana ma mua (e laʻana ka hopena, ka wehe ʻana i ka waiʻona).

Ma hope o ka wehe ʻia ʻana o ka waiʻona momona, hoʻoheheʻe ʻia ka mea hana alkyl polyglycoside i loko o ka wai i mea e hoʻokumu ʻia ai kahi pāpaʻi alkyl polyglycoside 50 a 70% nui loa. Ma nā ʻanuʻu hoʻomaʻemaʻe aʻe, hana ʻia kēia paʻi i kahi huahana o ka maikaʻi maikaʻi e like me nā koi pili i ka hana. Hiki i kēia mau hana hoʻomaʻemaʻe ke komo i ka bleaching o ka huahana, ka hoʻoponopono ʻana i nā hiʻohiʻona huahana, e like me ka waiwai Ph a me nā mea waiwai ikaika, a me ka microbial stabilization. I loko o ka palapala patent, he nui nā laʻana o ka hoʻomaʻemaʻe hoʻohaʻahaʻa a me ka oxidative bleaching a me nā kaʻina hana ʻelua o ka oxidative bleaching a me ka reductive stabilization. ʻO ka hoʻoikaika ʻana a no laila ke kumukūʻai e pili ana i kēia mau kaʻina hana no ka loaʻa ʻana o kekahi mau hiʻohiʻona maikaʻi, e like me ke kala, ma muli o nā koi hana, ma nā mea hoʻomaka, ka DP pono a me ka maikaʻi o nā kaʻina hana.

Hōʻike ka Figure 6 i kahi kaʻina hana ʻenehana no nā polyglycosides alkyl kaulahao lōʻihi (C12/14 APG) ma o ka synthesis pololei)

Ka manawa hoʻouna: Oct-13-2020